LulzBot Support

Legacy Printers

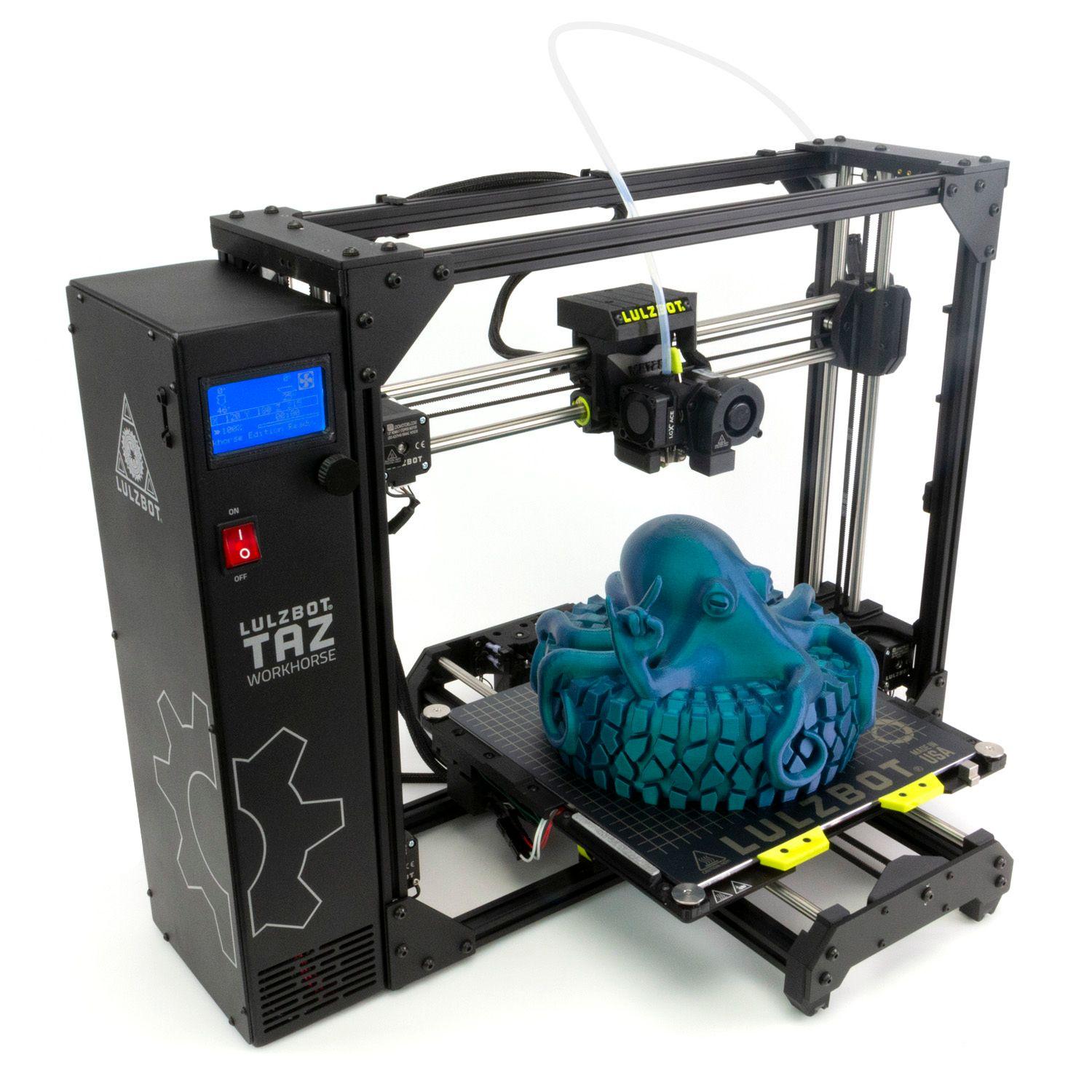

- TAZ Pro

- TAZ Pro S

- Taz Pro XT+

- TAZ Pro Long Bed

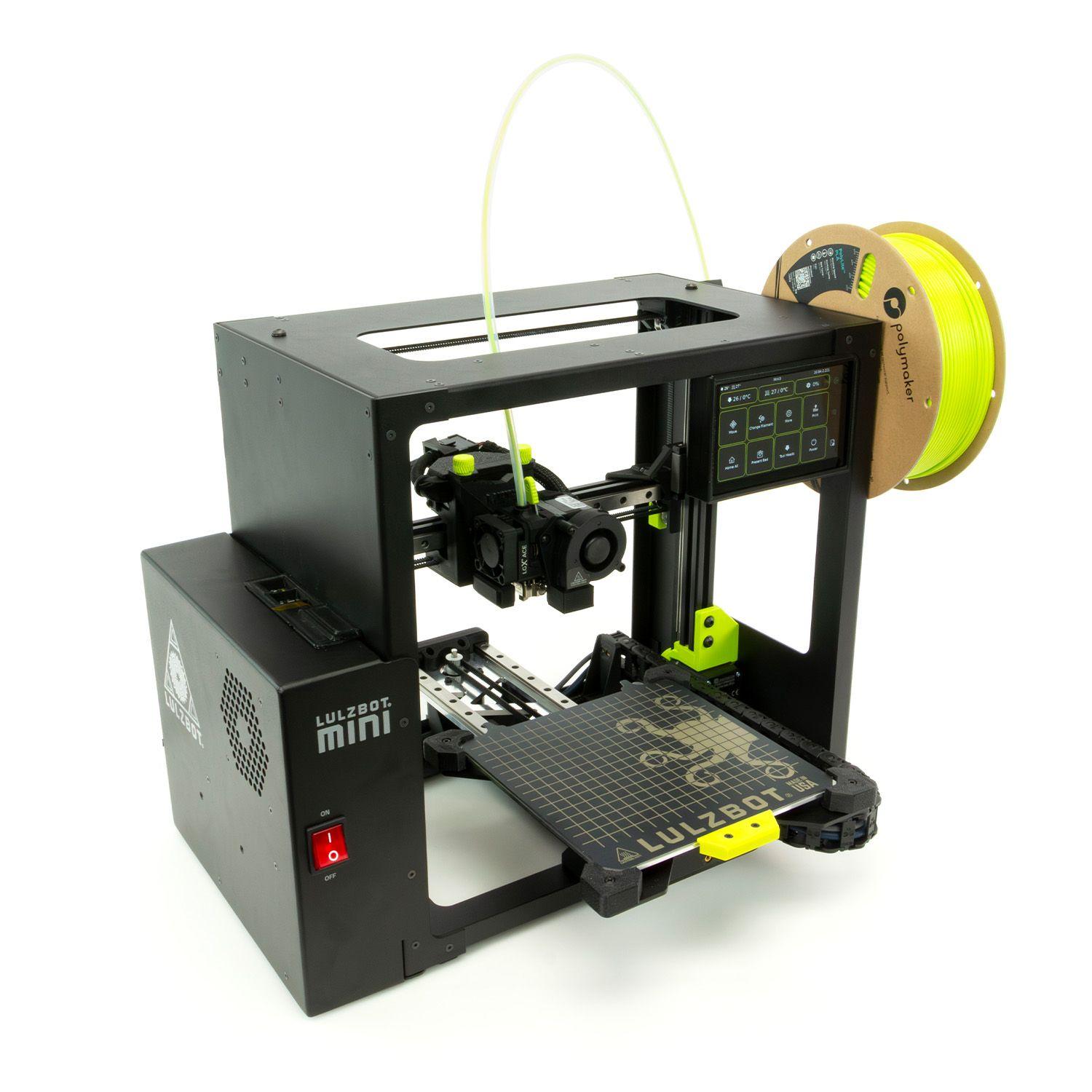

- LulzBot Mini 2

- LulzBot SideKick 289

- LulzBot TAZ 6

- LulzBot Mini 1

Quick Links

Documentation

Supported Software

Policies

- Shipping, Standard Warranty, and Returns

- Extended Warranty

- Repair Service

- Electronics Recycling

- Privacy Policy

Downloads

General Information