Learn

Print, STACK, Win: How LulzBot Brought Tic STACK Toe to Life

See how LulzBot turned Tic STACK Toe from concept to reality with rapid 3D printing, scalable U.S. production, and end-to-end design support.

A Business Built on TAZ 8 Print Power: As Seen on 3D Printing Nerd

See how the TAZ 8 print farm powers real-world innovation in RF testing - featured by 3D Printing Nerd in a behind-the-scenes look at MilliBox.

Go Big with the MegaSpool Feeder

Handle 5–10kg spools with ease. The MegaSpool Feeder ensures smooth, tension-free prints and fewer changeovers on most 3D printers.

TAZ 8: For Those Who Demand More

The LulzBot TAZ 8 delivers industrial-grade reliability, repeatability, and performance, making it the perfect tool for professional 3D printing and manufacturing.

TAZguard Enclosures Now Available!

Upgrade your printing with TAZguard Enclosures, designed to reduce warping and improve adhesion for all current and future TAZ series printers!

Meet the Mini 3: Rapid, Robust, & Reimagined!

Fast speeds, advanced connectivity, and reliable features make this 3D printer ideal for any setting. LulzBot Mini 3 available now!

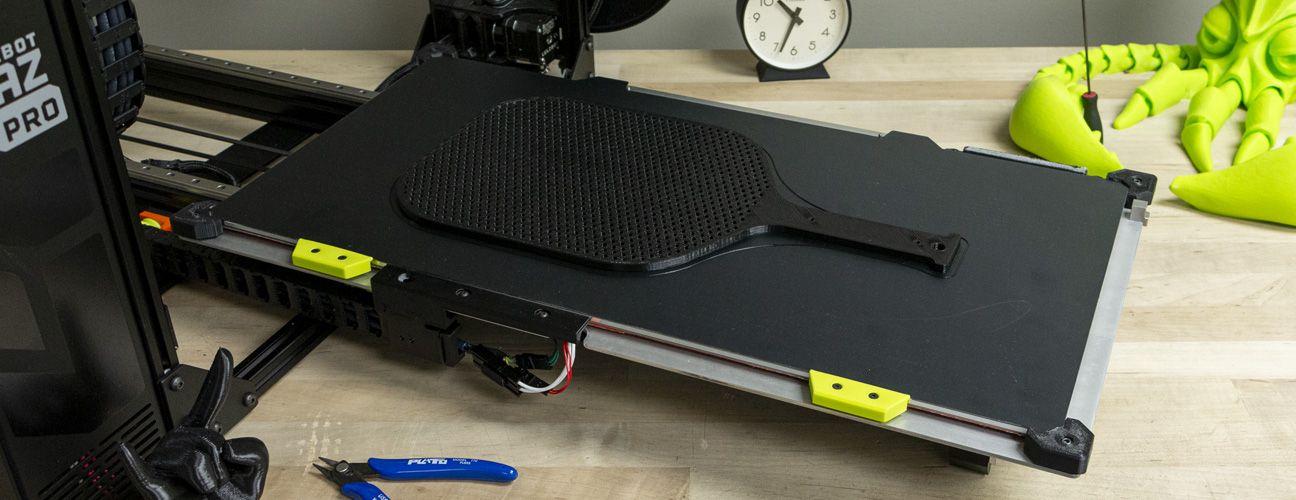

Racquet Science: 3D Print Your Own Pickleball Paddle (Free STLs)

Volley into summer with LulzBot! 3D print your custom pickleball paddle with LulzBot TAZ Pro Long Bed. Perfect for casual fun and showing off your creativity. Free stl files included!

Achieve 1000s of 3D Prints with a LulzBot Print Farm!

Turn-key LulzBot Print Farms optimize large-scale 3D printing with walls of printers, efficient AutoFarm3D™ software, and secure data management. Featuring a robust, customizable design and full-service setup, it's the ideal solution for advanced 3D printing needs. LulzBot Print Farms are now ready for order!

Redefining Reliability: The Upgraded TAZ Workhorse+

Whether you're already a LulzBot user or starting to produce 3D printed parts for the first time, the Workhorse+ offers a straightforward and simple 3D printing experience . With the Meteor 285, magnetic flex bed, new firmware, and runout sensor you get more convenience, ease of use, and reliability.

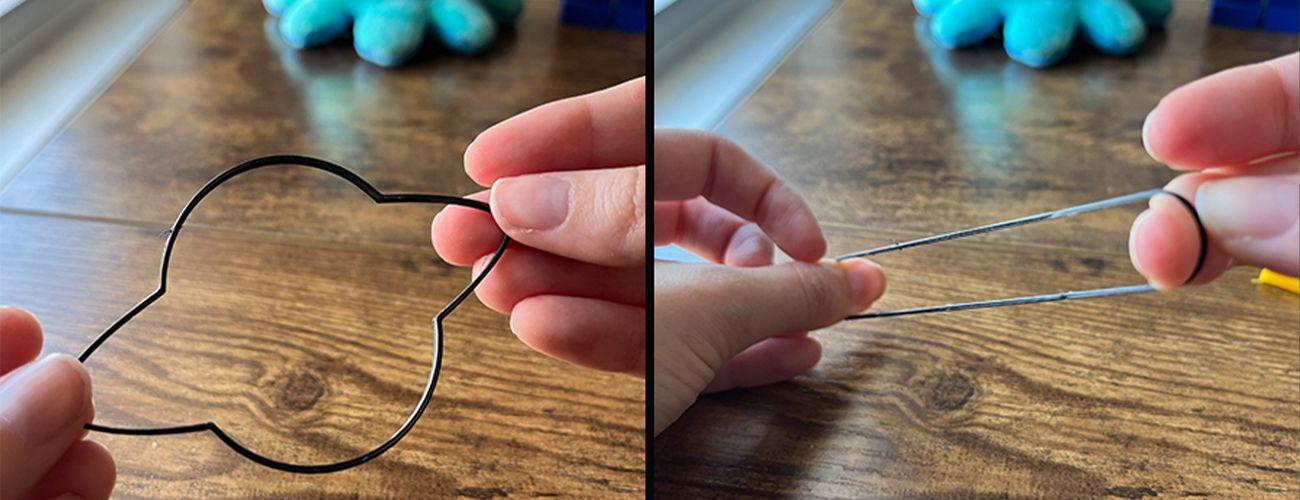

Love by Layers: 3D Printing a Valentine's Rose

This Valentine's Day, we're sharing a unique and effective post-processing technique for crafting a Valentine's Rose, hoping to inspire your own DIY heat-formed gift.

Exploring New Frontiers in 3D Printing: The Galaxy Series

Explore new frontiers with LulzBot's Galaxy Series. These five cutting-edge Tool Heads have been engineered to offer unparalleled reliability and versatility.

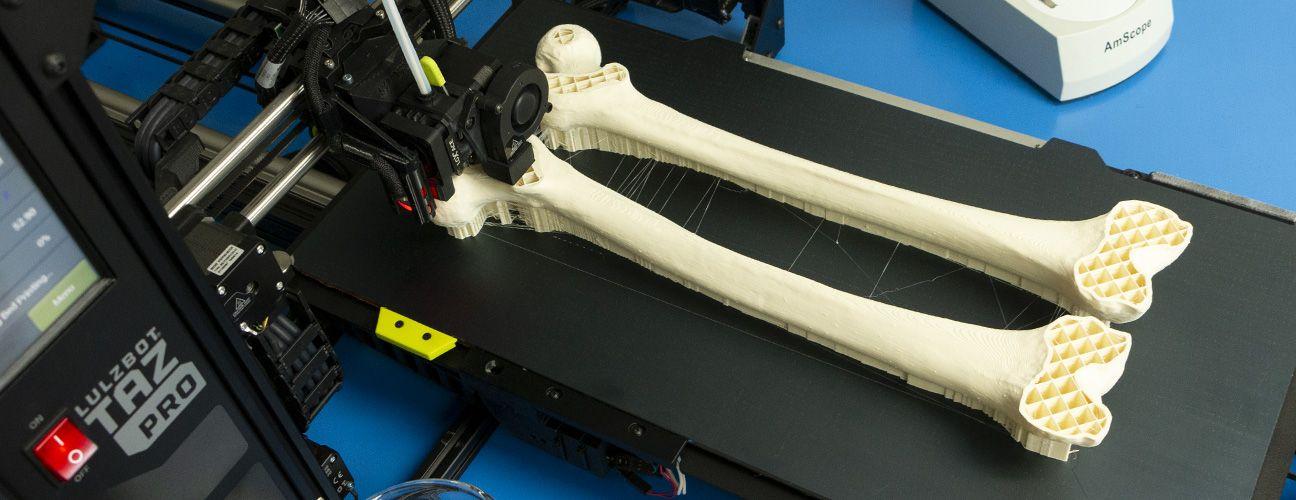

From Bytes to Bones: How We 3D Printed a Life-Sized Human Femur

In this article, LulzBot takes you through an exploration of 3D printing life-sized human bones using the TAZ Pro Long Bed 3D printer. 3D printing full-scale femur bones showcases not only the incredible size of the Long Bed, but also demonstrates a unique, hands-on learning experience. Dive into the world of 3D medical models with insights into the National Institutes of Health (NIH) 3D repository, a valuable...

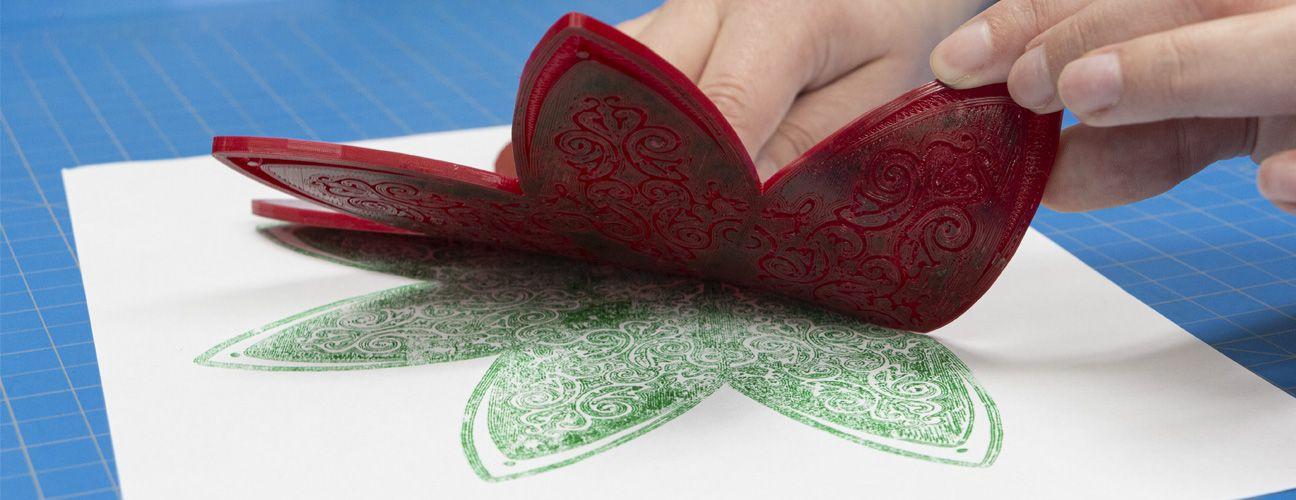

Red TPU Decking the Halls

The best time of year to sit down and craft together has to be the holiday season! This year, we wanted to break away from the old Christmas crafting stand bys of strings of popcorn and painted...

A New Spin On an Antique Slot Machine: Restoration with the TAZ Pro Long Bed

LulzBot users continually showcases impressive projects highlighting the utility of 3D printing. Unique builds like this antique slot machine restoration benefit from the technology, especially when original replacement parts have long disappeared. When these original parts are no longer available, 3D printing offers...

Mini 2 Closeout: While Inventory Lasts!

As the year comes to a close, we are excited to announce a holiday closeout sale for our Mini 2 printer, now available for just $1295! This sale is the perfect opportunity for both new and experienced...

Introducing the TAZ Pro Long Bed - Maximize Your Y-axis!

We are excited to officially launch our newest 3D printer, the TAZ Pro Long Bed, a long-awaited addition to the TAZ Pro Platform. Thanks to its impressive build volume of 282 x 582 x 285mm, this machine immediately stands out with over double the build volume of a standard...

An Inside Look: Brunch Layer-by-Layer

A day marked by good food at a great company. Read about how LulzBot prints their own special spin on employee appreciation events!

Printing TPU/TPE on Your LulzBot

3D printed parts don’t have to just be made of PLA, ABS, PETg, or other hard plastics! Your LulzBot 3D printer is already equipped to enable you to print with any TPU or TPE filament. Learn about some of the common flexible filaments on the market and the tips and tricks to start printing them today.